Manufacture

Metals and alloys

The basis for creating a wedding ring is laid by melting metals and alloys of the required size and temperature.

At this point, as the Lars Alyans family, we mix and melt more than 20 precious metals in our production area.

The foundry is a unique place where each precious metal is individually heated under intense heat.

Lars Alyans has a wide range of alloys.

Our range of gold alloys includes green, white, pink, red, grey, ivory, honey, hazelnut and apricot.

Our goal is to satisfy our customers with our wide selection of alloys and unique manufacturing of wedding rings.

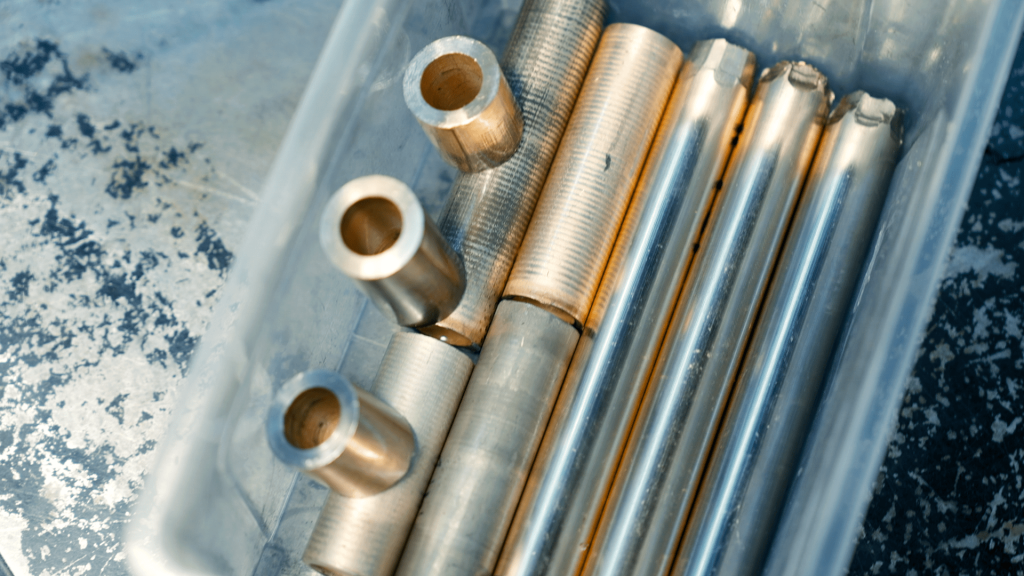

Alloy to the pipe

Pipes are cast from metal through which hot liquid flows.

The thickness of the pipes is then reduced by rolling.

During this rolling process, the density of the pipes increases and they harden. This allows you to have wedding rings made from a single piece of ring without soldering, which you can use for longer.

The rings then continue their production journey on manual or advanced CNC machines.

Ring formation

In our next step, the profile shape and size is given to the empty ring.

In this step, the rings are turned manually or using the most modern CNC machines. At this stage the rings receive their individual profile, width and height.

At this stage, your custom wedding rings begin to take shape. The product gets its identity.

After each transaction, the rings are carefully examined by our experienced colleagues.

Stone nailing

Our stone setters require concentration and high hand precision when placing stones.

As Lars Alyans we have a large selection of stones. We offer diamonds in baguette, princess and heart shapes and in various colors, especially diamond cut.

Our goal does not end with just carrying stones. By offering multiple stone setting options, we want to ensure that the ring and stones harmonize and have a unique product identity.

Shiny or matte

Shine is achieved on wedding rings by polishing. This job requires extreme sensitivity.

The trained eye of our experienced polishers is far superior to any machine calculation. Polishing is therefore purely manual work.

The surface structure of the wedding ring is a powerful design element.

Personal

Each wedding ring becomes absolutely unique through carving.

Lars Alyans can create all types of engravings, from names and dates to drawings, using modern laser technology.

After your rings have been manufactured in our factory, we turn your engraving template into reality.

Every engraving is a delicate work. Before the laser starts working, the ring must be positioned precisely. Concentration and skill are essential for this.

Quality control

In the final production step, the quality of the finished wedding ring is checked.

Every detail is checked under the microscope: height, width, cross section, profile, surface, stone setting and engraving.

Your product has passed through many qualified hands during the production phase. LARS ALYANS in Istanbul, Turkey, was founded with a lot of love and expertise as well as great passion.